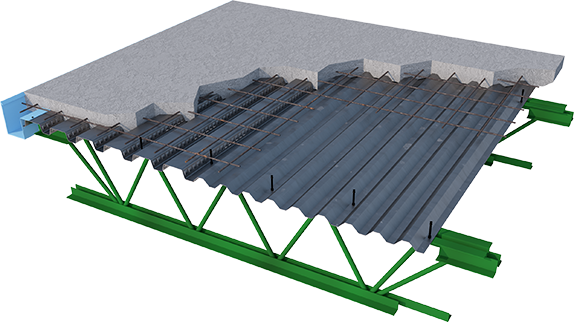

The Ecospan® Structural Floor System provides innovative, results-driven building solutions that surpass industry standards for safety, design flexibility, sound mitigation and fire ratings. Fabricated at Vulcraft plants throughout the U.S., Ecospan’s high-strength to weight ratio makes it ideally suited for multistory residential and commercial buildings. It incorporates the benefit of open web configuration along with 48” to 72” joist spacing, allowing for maximum design and installation flexibility of HVAC and Electrical systems.

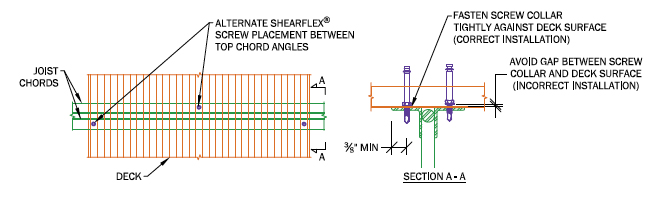

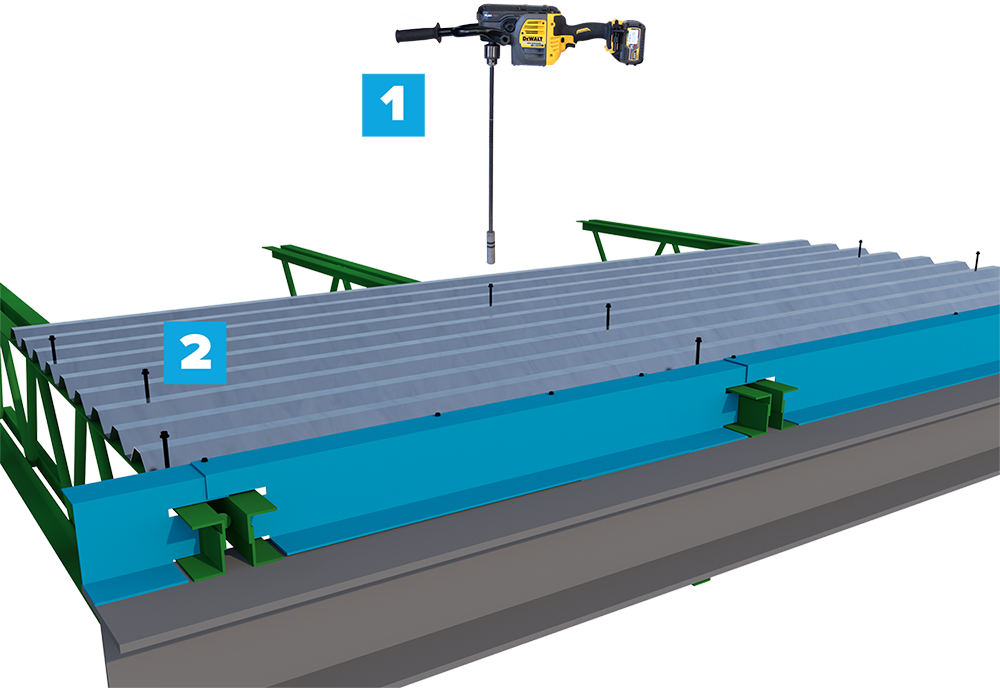

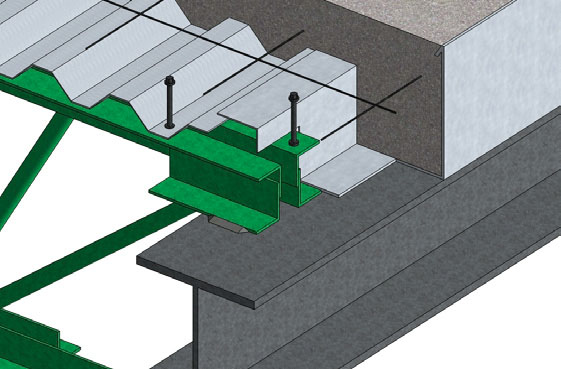

Ecospan is easy to install with the use of the Shearflex® Fastener that not only attaches the deck to the joists but also acts as the shear connector between the steel and the concrete. This system can be installed without the need for welding equipment.

It can be difficult to balance the demands of your clients and architects, all while trying to meet the structural requirements of a project at the same time. With Ecospan, you gain more flexibility in a building’s design with steel joists that have high strength-to-weight ratios, allowing for greater spans and spacing with lighter members. Ecospan also has joist orientation flexibility.

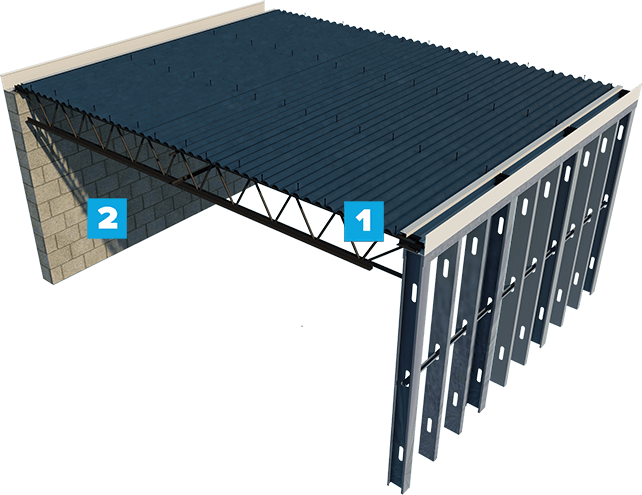

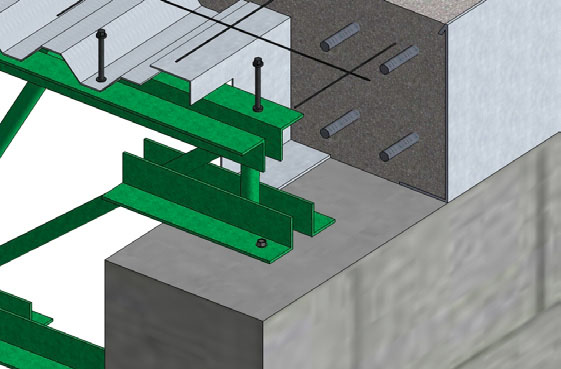

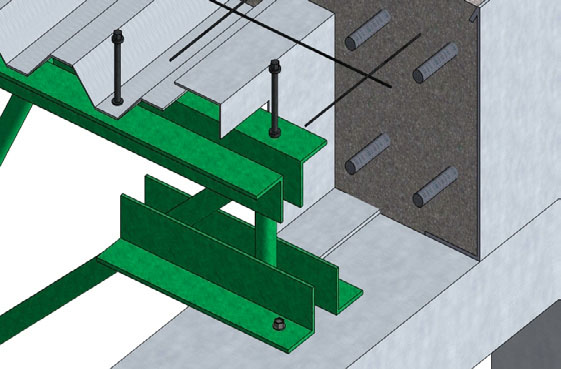

The Ecospan System enables you to span from the exterior to corridor or demise wall to demise wall. It can also be supported by virtually every framing system:

The Ecospan System over-delivers on value toward each project. There are many reasons why the Ecospan System delivers a very economical solution for your next project.

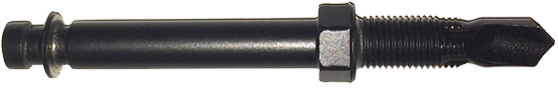

The “key” to the whole system, the Ecospan Shearflex fastener not only provides the shear connection between the steel and the concrete, but it is also the fastening device for attaching the deck to the steel joists. In one quick motion, two steps are done.

This self-drilling, self-tapping fastener provides the following benefits:

This self-tapping, self-drilling, Dual Process heat-treated Shearflex Shear connector creates a composite design, allowing for shallow, lightweight, longer span joists with greater rigidity; also providing a diaphragm.

This manual is for Design Professionals who are intending to design and use the Ecospan® Structural Floor System. It has been prepared in accordance with recognized engineering principles and is for general information only.

Ecospan® helped one customer save over $1M in materials costs and finishing the project 4 months ahead of schedule.

Homewood Suites in Steamboat Springs, Colorado is an 87-room, four-story hotel. See the benefits of using Ecospan®.

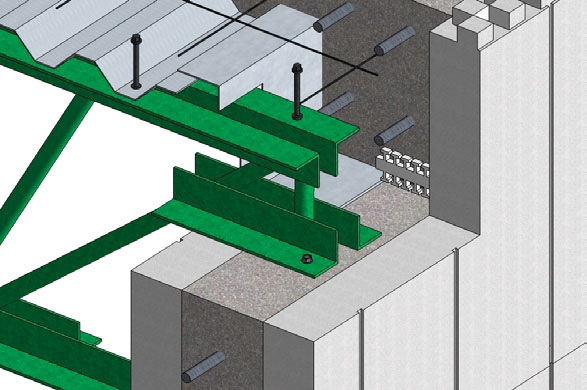

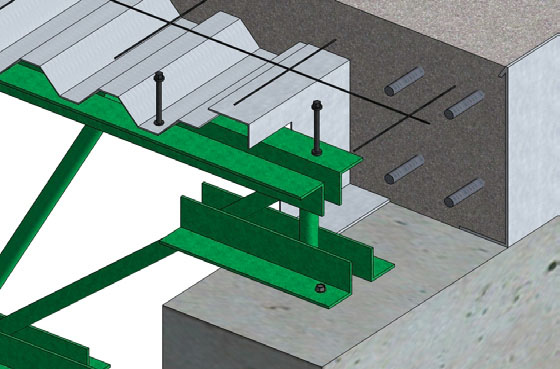

Compatible with Structural Steel

Compatible with Masonry

Compatible with Light Gauge Steel Stud

Compatible with Insulated Concrete Forms

Compatible with Concrete

We know that safety on the job site is paramount. With Ecospan, you can improve safety and reduce your construction liability since this system utilizes longer sheets of light-gauge decking that are easy and inexpensive to install. Using the Shearflex Fastener and Shearset Tool, you can attach the deck to joists in just a single step.

With fire safety and regulations always a concern when starting new projects, Ecospan has gone above and beyond to make sure you’re safe and up to code. Ecospan has a UL List Fire Rating of G-561 for 1, 2 and 3 hours with gypsum board ceilings; a ULG-229 listing that provides for the use of acoustical materials for suspended ceiling applications; and a ULG-710 listing that allows for “spray-on” applications for commercial and medical projects.

The Ecospan Structural Floor System by Nucor/Vulcraft is an innovative, effective and economical method of providing all-steel, open web structural components for elevated floor construction while incorporating the benefits of lighter weight composite design. Ecospan requires only a nominal 3” thick, 3,000 psi concrete slab, with no shoring or stripping of framework needed. The open web configuration and 48” on center joist spacing allows for HVAC and electrical design flexibility. And erectors will love Ecospan because it utilizes standard steel joist and deck components with which they’re already familiar. Plus, it’s mechanically fastened, so it’s easy for less experienced workers to quickly and effectively install. These are just a few examples of how the Ecospan Structural Floor System is a safe and easy choice for your next project.

The Ecospan Structural Floor System is listed by Underwriters Laboratories Inc. with multiple Fire Ratings for Acoustical and Gypsum ceiling applications. Click a Design No. below to see it’s corresponding Fire Rating web page.

| UL Code | Application |

|---|---|

| Design No. G561 | Direct Applied & Suspended Gypsum Board Ceiling |

| Design No. G229 | Suspended Acoustical Ceiling |

| Design No. D916 | Composite Deck (used in corridors) |

| Design No. G213 | Suspended Acoustical Ceiling |

| Design No. G222 | Suspended Gypsum Board Ceiling |

| Design No. G227 | Suspended Acoustical Ceiling |

| Design No. G236 | Suspended Acoustical Ceiling |

| Design No. G243 | Suspended Acoustical Ceiling |

| Design No. G547 | Suspended Gypsum Board Ceiling |

| Design No. G710 | Spray-On Fire Proofing |

| Design No. N789 | Spray-On Fire Proofing |

The Ecospan Composite Floor System has been tested by a renowned acoustical laboratory where the system received an STC (Sound Transmission Classification) of 57. In addition, many tests were performed with various common flooring materials and in all cases, the results exceeded an Impact Insulation Classification (IIC) of 50 (the IBC Code minimum), when typical sound attenuation materials were used.

Click on the image to view the Ecospan STC and IIC ratings.